Difference Between Thermal Interface Materials

Thermal Interface Materials (TIMs) are essential in electronics for managing heat transfer between components. They help reduce thermal resistance, allowing heat to flow from heat-generating parts like CPUs to cooling devices such as heat sinks. Below are the top five types of TIMs, each offering distinct advantages depending on the application.

-

Thermal Tape vs. Paste vs. Pad

When it comes to managing heat in el… LEARN MORE…

-

Silicone vs. Silicone-Free

Silicone vs. Silicone-Free Thermal I… LEARN MORE…

-

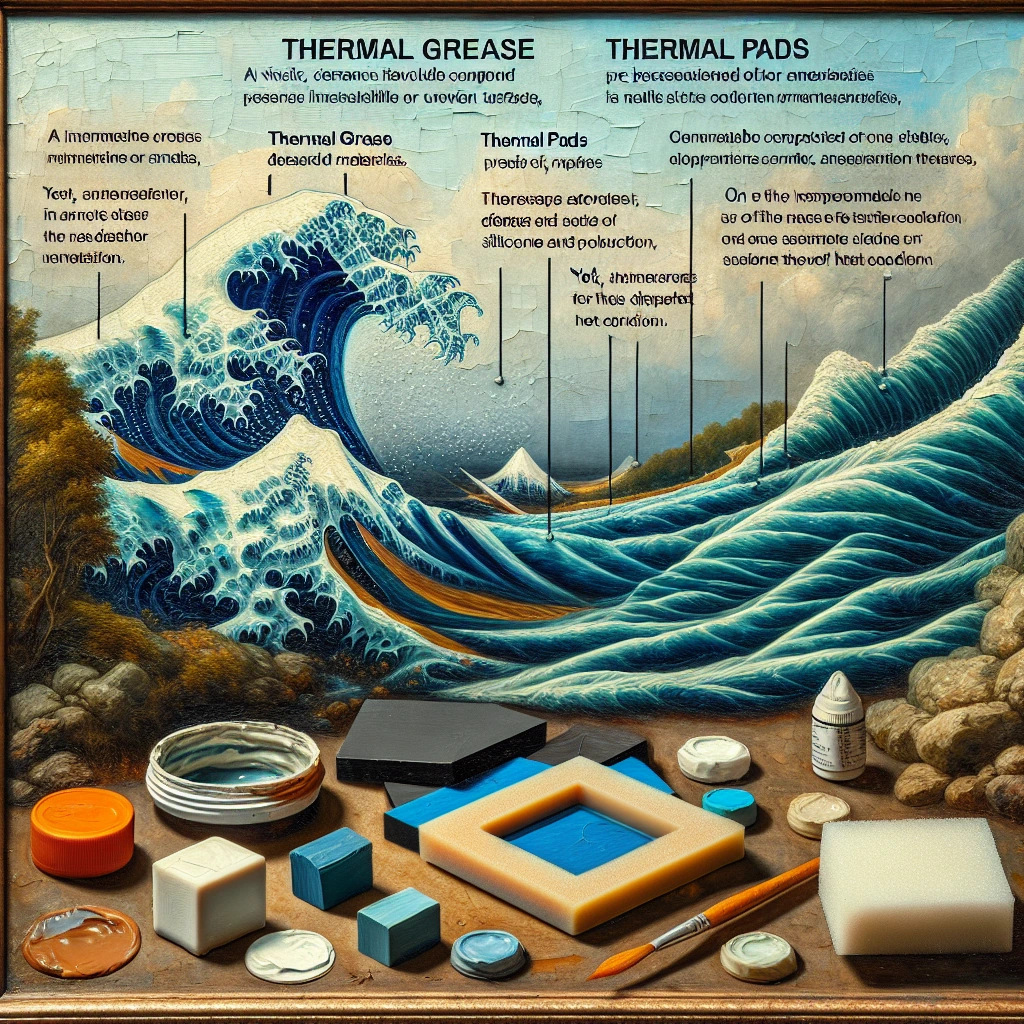

Thermal Grease vs. Thermal Pad

Key Differences and Application Guid… LEARN MORE…

-

Thermal Gel vs. Thermal Pad

Choosing the Right Thermal Interface… LEARN MORE…

-

Thermal Putty vs. Thermal Pads

Thermal putty and thermal pads are b… LEARN MORE…

-

Thermal Putty vs. Thermal Gel

Understanding Thermal Putty and Ther… LEARN MORE…

-

Thermal Grease vs. Thermal Putty

Which One to Choose for Heat Managem… LEARN MORE…

-

Graphene instead Vapor Chamber

Why did Apple use Graphene instead S… LEARN MORE…

1. Thermal Pad / Thermal Tape

Thermal Pads and Thermal Tapes are solid, pre-formed sheets made from materials like silicone or other polymers filled with thermally conductive compounds. These are applied between surfaces to fill small air gaps and improve heat transfer.

Advantages:

- Easy to apply: Pads and tapes come in pre-cut forms, making them easy to install without needing precise application.

- Durable: They offer long-lasting performance and don’t degrade as quickly as other TIMs.

- Clean application: No mess involved compared to pastes or gels.

Disadvantages:

- Lower thermal conductivity: They generally have lower thermal performance compared to liquids like thermal grease or gel.

- Less flexibility: They may not fill very small or complex gaps as effectively.

2. Thermal Grease / Thermal Paste

Thermal Grease, also known as Thermal Paste, is a viscous material that provides efficient thermal conductivity between components. It’s commonly used in applications like CPUs and GPUs, where precision cooling is needed.

Advantages:

- Excellent thermal conductivity: Grease offers superior performance by filling microscopic air gaps.

- Cost-effective: It’s widely available and relatively inexpensive.

Disadvantages:

- Messy and difficult to apply: Applying the right amount of grease can be tricky, and it may spill out, making cleanup difficult.

- Requires reapplication: Over time, thermal grease can dry out, reducing its effectiveness and requiring replacement.

3. Thermal Gel

Thermal Gel is a flowable material that can be applied similarly to thermal grease but offers more flexibility and durability. Once applied, it stays in place and maintains consistent performance over time.

Advantages:

- Flexibility: Thermal gel is more resilient and less likely to dry out compared to grease.

- Superior gap-filling ability: It can handle uneven or larger gaps with ease.

- Good thermal conductivity: Like thermal grease, gel efficiently transfers heat between components.

Disadvantages:

- Higher cost: Gels are typically more expensive than thermal grease.

- Specialized application: It may require precision tools for proper placement.

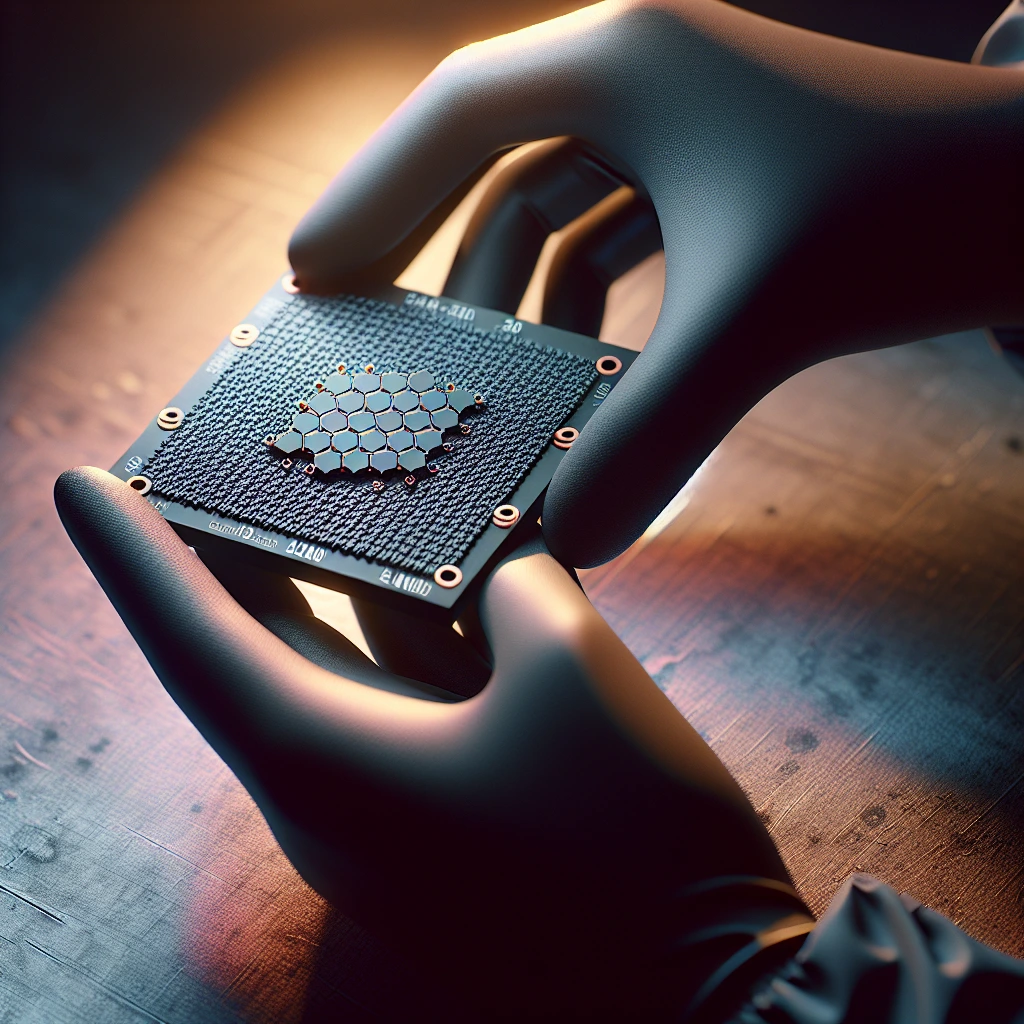

4. Graphite / Graphene Sheets

Graphite and Graphene sheets are increasingly used in advanced electronic cooling due to their excellent thermal conductivity. They are ultra-thin, lightweight, and efficient at spreading heat across a large surface area.

Additionally, graphene sheets are flexible and can be easily molded or cut into various shapes, allowing them to fit seamlessly into the complex internal structure of modern smartphones.

Advantages:

- Superior thermal conductivity: Graphite and graphene are among the most efficient materials for heat transfer.

- Lightweight and flexible: These sheets are extremely thin and can fit into tight spaces in modern devices.

- Electromagnetic shielding: Graphene also helps reduce electromagnetic interference, improving device stability.

Disadvantages:

Higher cost: Graphite and graphene materials tend to be more expensive than traditional thermal interface materials.

But Graphene is relatively inexpensive to produce compared to vapor chambers, making it a more economical option for mass production.

5. Thermal Absorbers

Thermal Absorbers are specialized materials that not only conduct heat but also absorb and dissipate electromagnetic radiation. They are often used in applications where both heat management and electromagnetic interference (EMI) reduction are important.

Advantages:

- Dual functionality: Thermal absorbers handle both heat and EMI issues, improving overall device performance.

- Customized shapes: They can be cut or molded to fit specific components.

Disadvantages:

- Costly: Due to their advanced properties, thermal absorbers are more expensive than basic thermal pads or grease.

- Limited availability: They are often used in specialized applications, making them less commonly available.

Conclusion

When selecting a thermal interface material, it’s essential to balance cost, ease of application, and thermal performance. Thermal pads/tape offer simplicity and cleanliness, while thermal grease and gel provide higher thermal conductivity for demanding applications. Graphite/graphene sheets are excellent for advanced heat dissipation and EMI protection, whereas thermal absorbers offer dual functionality for both heat and electromagnetic management. The right choice depends on your application’s specific needs and the level of thermal management required.

LiPOLY TIM Technology : Thermal Solutions