Silicone Thermal Liquid Gap Filler

Silicone Thermal Liquid Gap Filler are highly valued for their flexibility and excellent thermal conductivity. These fillers are ideal for applications that demand a material capable of conforming to complex geometries and uneven surfaces. The liquid form allows for easy application, ensuring that even the smallest gaps are filled, which is critical for maintaining optimal thermal contact.

One of the key advantages of Silicone Thermal Liquid Gap Filler is their ability to withstand a wide range of temperatures. They remain stable and effective under thermal cycling, making them suitable for use in automotive electronics, telecommunications, and other environments where devices are exposed to varying temperatures. Additionally, silicone fillers offer excellent electrical insulation, which is essential for protecting sensitive electronic components from electrical shorts.

Thermal Conductive Putty

LiPOLY’s Putty Series is gap filler material with a thermal conductivity 3.5~10.0W/m*K, high deformation amount, extremely low thermal resistance, low stress, flexible gap adaptation, and excellent tolerance compensation feature can overcome overflow and dryness problems. Ideally suited for LiPOLY Smart Dispense Robot which is the best choice for automated dispensing production.

Two-Part Thermal Conductive Gap Filler

LiPOLY’s DM series is two-part compound gap filler that can be cured at room temperature or high temperature. Compared with thermally conductive pad, the Two-Part Thermal conductive Gap filler not only produces low stress, high thermal conductivity, and low viscosity on the components, but also maintains insulation properties. Thermal conductivity: 2.2~7.0W/m*K. Ideally suited for LiPOLY Smart Dispense Robot which is the best choice for automated dispensing production.

Two-Part Thermal Conductive Sealing Glue

LiPOLY’s TPS series is a two-part compound sealing glue that can be cured at room temperature or high temperature. The sealing glue is a liquid fluid thermally conductive adhesive that can fill the gaps in the air space around electronic devices. After curing, it will interact with heating electronic components and radiators, so that electronic products can run at high power for heat conduction. It’s a nice gap filler material with thermal conductivity 0.8~2.0W/m*K.

Two-Part Curable Thermal Grease

LiPOLY’s D2000 is a two-part compound thermal grease that can be cured at room temperature or high temperature. It’s properties of extremely low thermal resistance and high reliability cause no dryness and overflow.

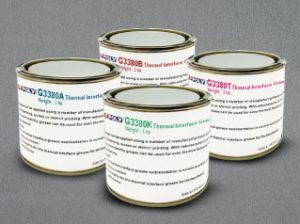

Thermal Grease

LiPOLY’s G and TT series is thermal grease with extremely low thermal resistance and good thermal conductivity features. They have been widely used in thermal control technology for consumer electronics and microprocessors. When the temperature of the components rises the viscosity of the grease will decrease for wetting interface element. Thermal conductivity: 1.3-6.0W/m*K, it’s a nice gap filler material.

Two-part Thermal Conductive Die-Attach Adhesive

LiPOLY’s TIM12/TIM14 is a two-component thermally conductive adhesive that can be cured at high temperature. It not only produces low stress, low thermal resistance, and good adhesion to components, but also maintains excellent insulation properties. Thermal conductivity is 2.0-4.0W/m*K. TIM 1 material is suitable for automated dispensing operation.

LiPOLY TIM Technology : Thermal Solutions

Do you have some questions? Please don’t hesitate to send us an email: [email protected]