Silicone Thermal Gap Pads

Silicone-based thermal gap pads are widely used in many industries due to their excellent thermal conductivity and flexibility. Silicone pads are soft, compliant, and capable of conforming to uneven surfaces, ensuring full contact between components and heat sinks. This adaptability is crucial in applications where components vary in height or shape, making consistent thermal contact a challenge.

One of the standout features of silicone-based pads is their durability. They can withstand a wide range of temperatures and environmental conditions, making them suitable for use in automotive electronics, telecommunications, and consumer electronics. Their ability to maintain performance over time under mechanical stress and temperature fluctuations makes them a reliable choice for long-term thermal management.

High Thermal Conductive Gap Filler

LiPOLY’s T series is an extremely high-performance thermally conductive pad, with excellent insulation, compressibility, and soft characteristics that can fill gaps exhibit a very low thermal resistance effect. They can be customized die-cut and shape molding. Shiu Li has professional research and development capabilities which can provide cutting-edge thermal solutions immediately to meet all customers’ need for today’s advanced products.

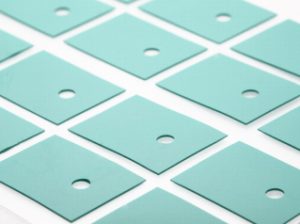

Thermal Conductive Gel Pad

LiPOLY’s PK series is an excellent gap filler material with thermal conductivity 2.0~7.0 W / m*K. The hardness is Shore OO/30-50 with high flexibility, high compressibility, high insulating, great self-adhesive, which can remove manufacturing tolerances. Customized die-cut and shape molding are all available.

Exceptionally Soft Thermal Conductive Gel Pad

LiPOLY’s BS series is an ultra-soft thermally conductive gel pad with high resilience characteristics which can avoid the deformation of PCB and other components caused by assembly stress. Thermal conductivity: 3.0~5.0W / m*K and hardness Shore OO/10-25 provide high flexibility, high compressibility, high insulation and good self-adhesiveness. It can cover the tolerance of design making it very stable, also can offer customized die-cut & shape molding service.

Ultra Low Oil-Bleed Thermal Conductive Gel Pad

LiPOLY’s AS series has low oil-bleeding characteristics under high compression which can prevent the product from polluting electronic components due to silicon oil seepage, or combining with dust in the environment, causing dirt and affecting product appearance. It’s a best choice of gap filler material with thermal conductivity: 2.0~4.0W/m*K. Hardness Shore OO/30~40 provides flexibility, compressibility and insulation. Shiu Li has professional research and development capabilities which can provide cutting-edge thermal solutions immediately to meet all customers’ need for today’s advanced products.

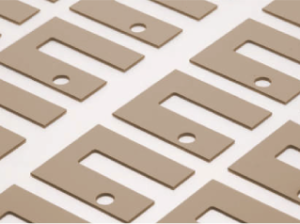

High Ductile Thermal Conductive Pad

LiPOLY S393&S818 is a product with high ductile thermal conductivity. Having good stretchability and high deformation. The toughness structure can enhance the operability and durability of material. It won’t easy to break and deform whether stamped, punched, strip type, or custom cutting. Your best choice for shock and tolerance absorbing.

Ultra Thin Thermal Film

LiPOLY AS02 is a material with double sided inherent tack, low thermal resistance and high thermal

conductivity. It has excellent compressive strength characteristics and good electrical isolation function

for high-power electronic components, making it the best choice for thin design installation.

Customized Die-Cut and molding are available.

LiPOLY TIM Technology : Thermal Solutions

Do you have some questions? Please don’t hesitate to send us an email: [email protected]