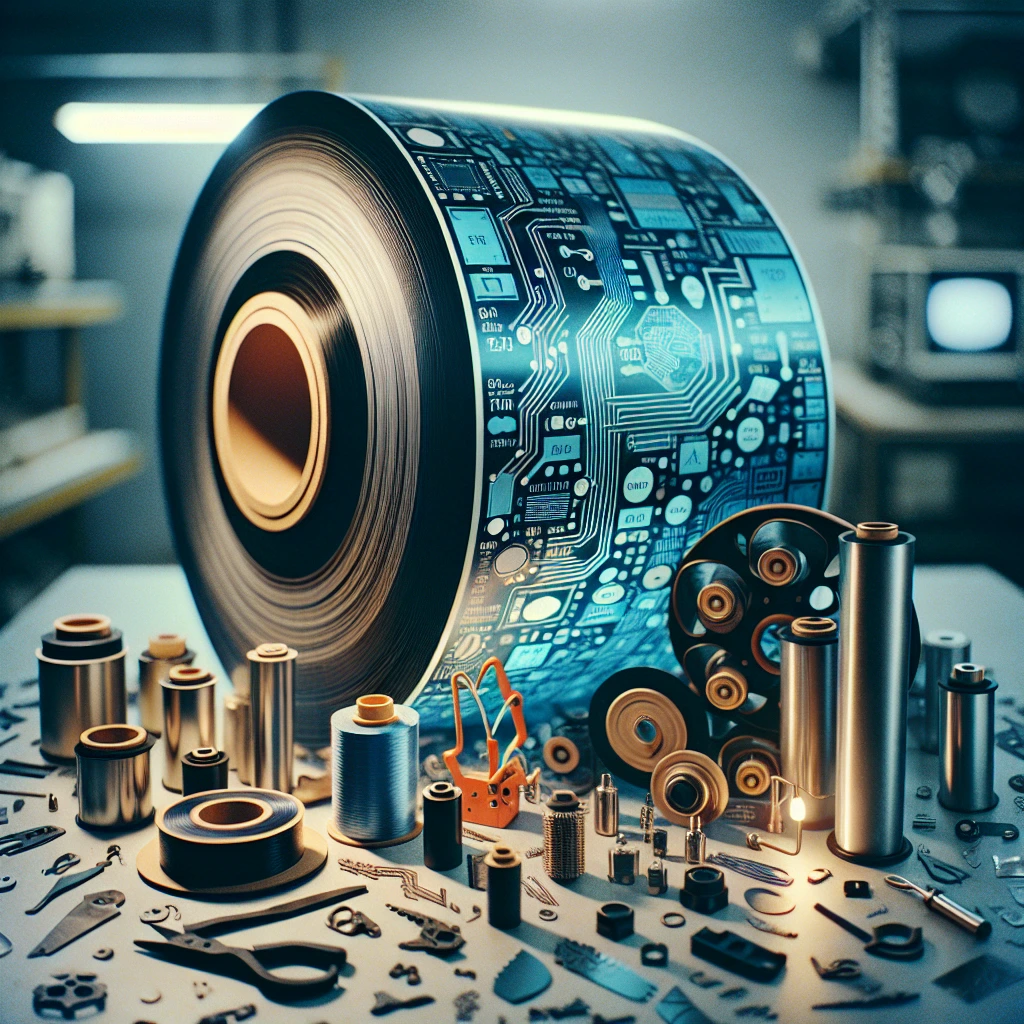

LiPOLY PR27 is very thin Films for Electrical Insulation with a thickness of 0.15mm. It uses Polyimide Film as the reinforcement material, which can increase the tensile strength. It’s suitable for high power transistors, electrical equipment, and will be the best choice for auto-distribution systems.

FEATURES

/ Thermal conductivity:1.8 W/m*K

/ Good insulator

/ Low thermal impedance

/ Reworkable

/ High performance

TYPICAL APPLICATION

/ Power supplies

/ Motor controls

/ Power semiconductors

/ 5G base station & infrastructure

/ EV electric vehicle

SPECIFICATIONS

/ Roll form

/ Sheet form

/ Die-cut parts

/ Single-sided adhesive or double-sided adhesive can be used as required

Table of Contents

PR27 Datasheet

Thermal Films for Electrical Insulation: An Overview

Thermal films for electrical insulation are specialized materials designed to provide both thermal management and electrical isolation in electronic devices. These films are essential in applications where maintaining optimal operating temperatures and ensuring electrical safety are critical.

Key Features of Thermal Films for Electrical Insulation

- Thermal Conductivity: These films are engineered to efficiently transfer heat away from electronic components, minimizing the risk of overheating. For example, LiPOLY PR27 offers a thermal conductivity of 1.8 W/m·K.

- Electrical Insulation: They provide excellent dielectric strength, ensuring that electronic components remain electrically isolated from conductive surfaces. Polyimide films, for instance, are known for their high electrical insulation properties.

- Material Composition: Common materials include polyimide and polyester, which offer a balance of flexibility, durability, and thermal performance. Polyimide films are particularly noted for their high temperature resistance and mechanical stability.

- Versatility: These films can be customized in terms of thickness and form (e.g., rolls, sheets, die-cut parts) to suit various applications.

Applications of Thermal Films for Electrical Insulation

- Power Electronics: Used in power supplies, motor controls, and power semiconductors where both thermal management and electrical isolation are necessary.

- Automotive Systems: Suitable for use in electric vehicles (EVs) and automotive control components where reliability under varying temperatures is crucial.

- Telecommunications Equipment: Employed in 5G base stations and infrastructure to manage heat efficiently while ensuring electrical safety.

- Optical Devices: Ideal for sensitive optical applications where silicone contamination must be avoided.

Advantages Over Other Insulating Materials

- High Performance: Thermal films provide a combination of high thermal conductivity and excellent electrical insulation, making them ideal for high-power applications.

- Durability: These films are resistant to high temperatures, chemicals, and mechanical stress, ensuring long-term reliability even in harsh environments.

- Reworkability: Some thermal films, like LiPOLY PR27, are reworkable, allowing for adjustments during assembly without compromising performance.

Conclusion

Thermal films for electrical insulation are vital components in modern electronics, offering effective heat dissipation while ensuring electrical safety. Their versatility and high performance make them suitable for a wide range of applications across industries such as automotive, telecommunications, and power electronics. By selecting the appropriate thermal film, manufacturers can enhance the performance and longevity of their products.

LiPOLY TIM Technology : Thermal Solutions