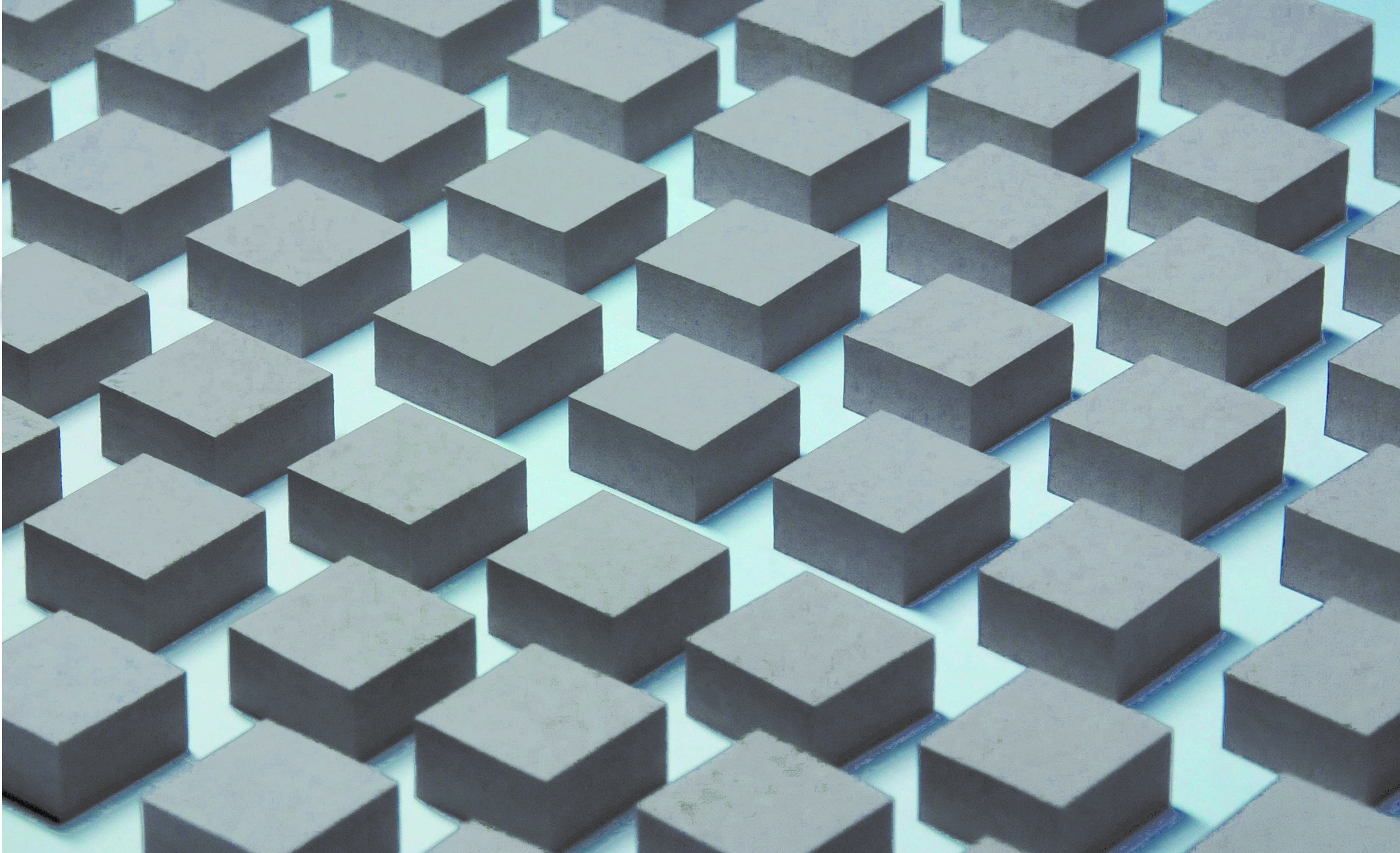

Non-Silicone Thermal Compound N700C is made of non-silicon resin material. No low molecular siloxane volatilization and low total volatile gas, no electrical contact & pollution problems. N700C is flexible and has great thermal conduction, Low compressive stress and high compressive characteristics can effectively reduce the stress load of components, so that the equipment only needs to bear less mechanical stress, and at the same time, it can have low thermal resistance and high thermal conductivity.

FEATURES

/ Thermal conductivity: 5.0 W/m*K

/ It’s made by non-silicone resin materials

/ Low contact thermal resistance

/ With electrical insulation

/ Outstanding thermal conductivity

/ Applicable to optical and sensitive electric components

TYPICAL APPLICATION

/ HDDS

/ Optical appliance

/ 5G base station & infrastructure

/ EV electric vehicle

TYPICAL APPLICATION

/ Sheet form

/ Die-cut parts

Table of Contents

N700C-s Datasheet

Non-Silicone Thermal Pads: A Comprehensive Guide

Non-silicone thermal pads are thermal interface materials (TIMs) designed for applications where silicone-based products are unsuitable, often due to concerns about silicone contamination. These pads are essential for improving heat dissipation between electronic components and heat sinks, especially in sensitive environments.

Key Features of N700C Non-Silicone Thermal Pads

- Silicone-Free Composition: Made from materials such as resins, acrylics, polyimides, or ceramics, non-silicone thermal pads avoid issues like siloxane volatilization and silicone oil seepage. This makes them ideal for applications in optical instruments and medical electronics.

- Thermal Conductivity: These pads typically offer thermal conductivity ranging from 1.5 to 8.0 W/m·K, which is comparable to some silicone-based pads.

- Electrical Insulation: They provide excellent electrical insulation properties, reducing the risk of short circuits in electronic applications.

- Mechanical Properties: Non-silicone thermal pads are known for their good tensile strength and abrasion resistance, making them durable for various industrial applications.

Applications of Non-Silicone Thermal Pads

- Sensitive Electronics: Used in environments where silicone contamination must be avoided, such as in high-end industrial control, telecommunications hardware, and medical devices.

- Automotive and Industrial Equipment: Suitable for automotive sensors, AI devices, fiber optic communication systems, and other industrial control equipment.

- Data Centers and Computing: Employed in data centers and computing devices where efficient thermal management is critical.

Advantages Over Silicone-Based Pads

- No Silicone Contamination: Non-silicone pads do not release silicone oils or siloxanes, preventing potential contamination issues in sensitive environments.

- Environmental Compliance: Many non-silicone thermal pads comply with environmental standards such as RoHS and REACH, making them suitable for eco-conscious applications.

Conclusion

Non-silicone thermal pads are essential for applications where silicone-based TIMs pose a risk of contamination or are otherwise unsuitable. With their effective thermal conductivity, excellent electrical insulation, and compliance with environmental standards, these pads offer a reliable solution for managing heat dissipation in sensitive electronic environments.

LiPOLY TIM Technology : Thermal Solutions