Non-Silicone Thermal Grease is a specialized thermal interface material (TIM) designed to provide effective heat dissipation without the drawbacks associated with silicone-based products. These greases are particularly beneficial in applications where silicone contamination must be avoided, such as in sensitive electronic components and optical devices.

FEATURES

/ Thermal conductivity: 1.3 / 3.2 / 4.5 / 6.0 W/m*K

/ No outgassing

/ Low thermal impedance

TYPICAL APPLICATION

/ CPU and chip coolers

/ Switching power supplies

/ LED appliance

/ Between any heat-generating component and heat sink

/ 5G base station & infrastructure

/ EV electric vehicle

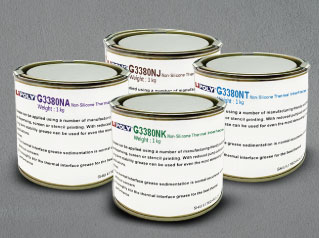

CONFIGURATIONS

/ Cartridges: 50ml

/ Tinplate Can:1kg

/ Other special and custom sizes are available upon request

Non-Silicone Thermal Grease

Key Features of Non-Silicone Thermal Grease

- Silicone-Free Composition: Non-silicone thermal greases are formulated using synthetic oils, or other non-silicone fluids. This composition eliminates issues like oil separation, migration, and contamination that can occur with silicone greases.

- High Thermal Conductivity: Many non-silicone greases offer comparable or superior thermal conductivity to their silicone counterparts.

- Low Thermal Resistance: These greases are designed to minimize thermal resistance, ensuring efficient heat transfer from components to heat sinks.

- Long-Term Stability: Non-silicone greases maintain their properties over time without drying out or cracking, which can be a problem with silicone-based products.

Advantages Over Silicone-Based Greases

- Reduced Contamination Risks: Non-silicone greases do not volatilize or bleed like silicone oils, reducing the risk of contamination in sensitive environments such as optical instruments and silicon-sensitive equipment.

- Environmental Compliance: Many non-silicone greases are RoHS and REACH compliant, making them suitable for eco-conscious applications.

- Versatility: These greases can be used in a wide range of applications, including CPUs, GPUs, LEDs, and power electronics, without the risk of silicone-related issues.

Applications

- Electronics: Ideal for use in CPUs, GPUs, and other chip components where high-performance thermal management is required.

- Optical Devices: Suitable for applications where silicone contamination must be avoided.

- Automotive and Industrial Equipment: Used in power semiconductors and motor controls where both thermal management and electrical insulation are critical.

Conclusion

Non-silicone thermal greases provide an effective solution for heat dissipation in sensitive electronic applications. By eliminating the risks associated with silicone oils, these greases offer reliable performance and long-term stability across various industries. Whether used in consumer electronics or industrial systems, non-silicone thermal greases ensure efficient thermal management without the drawbacks of traditional silicone-based products.

LiPOLY TIM Technology : Thermal Solutions