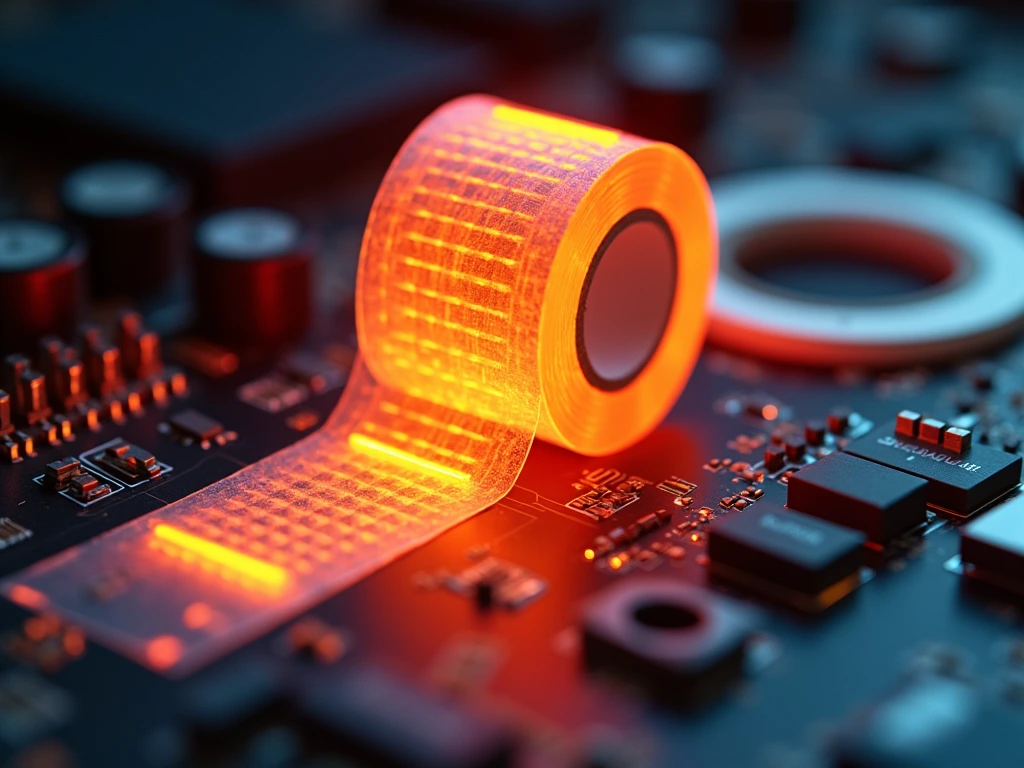

LiPOLY ST6000-S is a thermally conductive tape with UL Flammability high temperature heat resistance. The thermal conductivity is 1.8 W/m*K. The stickiness and strength of the thermal tape will increase when temperatures and pressure rise. They are designed to securely bond heat sinks to power dissipating components without an additional clamping mechanism.

FEATURES

/ Thermal conductivity:1.8 W/m*K

/ High temperature stability

/ Easy to assemble

TYPICAL APPLICATION

/ Power supplies

/ Motor controls

/ Power semiconductors

/ 5G base station & infrastructure

/ EV electric vehicle

SPECIFICATIONS

/ Roll form

/ Sheet form

/ Die-cut parts

Table of Contents

ST6000 Datasheet

Electrical insulator Tape [1.8 W/m·K] 🔗

UL Flammability Thermally Conductive Tapes: An Overview

Thermally conductive tapes with UL flammability ratings are essential components in electronic assemblies, offering both heat dissipation and safety features. These tapes are designed to transfer heat away from critical components while also meeting stringent safety standards, such as the UL 94 flammability rating.

Key Features

- Thermal Conductivity: These tapes are engineered with thermally conductive fillers, such as ceramic or metal particles, which help in efficiently transferring heat from hot surfaces to cooling devices like heat sinks.

- UL Flammability Rating: Many thermally conductive tapes achieve a UL 94 V-0 or V-2 rating, indicating their ability to self-extinguish and prevent the spread of flames. This makes them suitable for use in environments where fire safety is a concern.

- Electrical Insulation: In addition to thermal management, these tapes often provide electrical insulation, ensuring that electronic components remain isolated from conductive surfaces.

- Ease of Application: These tapes are typically pressure-sensitive and can be easily applied without the need for heat curing. They are available in various forms, including pre-cut shapes and rolls, facilitating quick and efficient installation.

Applications

- Electronics Cooling: Used extensively in high-density circuitry and electronic assemblies to manage heat dissipation efficiently. This includes applications in power semiconductors, MOSFETs, IGBTs, and other high-power devices.

- Automotive and Industrial Equipment: Suitable for automotive control components and motor controllers where both thermal management and electrical insulation are critical.

- Telecommunications and Data Centers: Employed in 5G base stations and data centers to ensure efficient heat transfer while maintaining electrical safety.

Advantages

- Safety Compliance: Achieving UL 94 ratings ensures that the tapes meet rigorous safety standards, making them reliable for use in critical applications where fire risk must be minimized.

- Versatility: These tapes can be used across various industries due to their excellent thermal and electrical properties. They are adaptable to different shapes and sizes, providing flexibility in design and application.

Conclusion

UL flammability thermally conductive tapes are vital for effective thermal management in electronics while ensuring compliance with safety standards. Their ability to provide both heat dissipation and fire resistance makes them indispensable in applications ranging from consumer electronics to industrial systems. By choosing the right thermally conductive tape, manufacturers can enhance the performance and safety of their products.

LiPOLY TIM Technology : Thermal Solutions