What is Thermal Gap Filler?

Thermal gap fillers are specialized materials designed to fill air gaps between electronic components and heat sinks, improving heat transfer and managing thermal issues. As electronic devices become more powerful and compact, the need for efficient thermal management solutions like thermal gap fillers has become increasingly critical. These materials help in dissipating heat, ensuring the reliable performance and longevity of electronic systems.

Thermal gap fillers are typically soft, compressible, and highly conformable materials, designed to fit into uneven or irregular surfaces. They provide superior thermal conductivity while maintaining flexibility, which is crucial for protecting sensitive components from excessive mechanical stress.

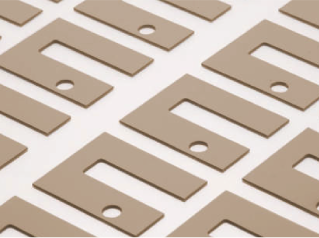

T-Top 800

LiPOLY’s Gap Filler provide deflection thermal interfaces between heat sinks and electronic devices, accommodating for uneven surfaces. LiPOLY’s R&D team have created an ultra-soft, highly conformable, non-flammable interface material. LiPOLY T-Top 800 is a high effective material, designed to allow minimal stress on components while offering high thermal conductivity and low thermal resistance. With a thermal conductivity of 8.0 W/m*K, T-Top 800 offers excellent performance at an extremely competitive price.

See the complete thermal datasheet by visiting: Thermal Gap Filler

LiPOLY TIM Technology : Thermal Solutions

Key Benefits of Thermal Gap Fillers

- Enhanced Thermal Conductivity: Thermal gap fillers are engineered to transfer heat efficiently between components and heat sinks or other cooling systems. By filling gaps, these materials minimize thermal resistance, allowing for more efficient heat dissipation. This is essential for high-performance devices that generate a significant amount of heat, such as processors, GPUs, and power electronics.

- Conformability and Flexibility: One of the most important features of thermal gap fillers is their ability to conform to the surface topography of components. Their soft and compressible nature allows them to adapt to irregular surfaces and varying gap sizes. This flexibility ensures optimal contact between components and heat sinks, further improving heat transfer.

- Vibration Dampening: In addition to their thermal properties, thermal gap fillers also serve as vibration dampeners. They help cushion sensitive components, protecting them from mechanical shock or vibrations that could cause damage over time. This feature is especially valuable in automotive, aerospace, and industrial applications where systems are exposed to constant motion.

- Electrical Insulation: Many thermal gap fillers offer electrical insulation properties, which is important for protecting components from electrical shorts or static discharge. This makes them ideal for use in densely packed electronic assemblies where both thermal and electrical insulation are required.

Types of Thermal Gap Fillers

There are two primary categories of thermal gap fillers: Silicone-Based and Non-Silicone solutions, each offering unique properties and suited for different applications.

Silicone-Based Thermal Gap Fillers

- Thermal Stability: Silicone-based gap fillers are known for their excellent thermal stability, making them suitable for high-temperature applications. They can maintain their thermal conductivity and physical properties even under extreme heat conditions, which is crucial for devices that generate a lot of heat, such as high-performance CPUs or industrial power supplies.

- High Conformability: These materials are extremely flexible, allowing them to conform to uneven surfaces, which is especially important in applications with complex geometries. Their compressibility ensures that they can fill gaps without exerting excessive pressure on components, preventing mechanical damage.

- Durability: Silicone-based thermal gap fillers are highly durable, able to withstand environmental stress such as moisture, UV exposure, and oxidation. This makes them suitable for outdoor applications or devices that operate in harsh conditions, such as telecommunications equipment or automotive electronics.

Non-Silicone Thermal Gap Fillers

- Contamination-Free: Non-silicone thermal gap fillers are often used in applications where contamination is a concern. For instance, silicone can sometimes release volatile organic compounds (VOCs) during operation, which may interfere with sensitive electronics or optical systems. Non-silicone alternatives eliminate this risk, making them ideal for environments where cleanliness is essential, such as medical devices, optical systems, or semiconductor manufacturing equipment.

- Chemical Resistance: Non-silicone gap fillers offer better resistance to certain chemicals, fuels, or oils, which can be crucial in specific industrial applications, including automotive and aerospace systems.

- Comparable Performance: While silicone-based materials are typically known for their flexibility, non-silicone gap fillers can provide similar levels of thermal conductivity and conformability, ensuring that they remain a viable option for applications requiring efficient thermal management.

Applications of Thermal Gap Fillers

Thermal gap fillers are widely used in various industries that require efficient heat management:

- Consumer Electronics: From smartphones to laptops, thermal gap fillers ensure that heat is effectively dissipated in compact devices, preventing overheating and prolonging product lifespan.

- Automotive: In electric vehicles, thermal gap fillers play a vital role in cooling powertrain components, battery packs, and control modules to enhance performance and reliability.

- Telecommunications: As telecommunications equipment generates significant heat, thermal gap fillers are used to maintain optimal operating temperatures in antennas, base stations, and other related devices.

- Medical Devices: In the medical field, non-silicone gap fillers are often chosen for sensitive devices where silicone outgassing could be a concern, providing efficient cooling solutions for diagnostic equipment and imaging devices.

Conclusion

Thermal gap fillers are an essential component in modern thermal management solutions, providing efficient heat dissipation in a wide range of applications. Whether you need silicone-based or non-silicone alternatives, these materials offer a versatile and reliable solution for ensuring the performance, safety, and longevity of electronic devices. By choosing the right thermal gap filler, you can protect your components from overheating, vibrations, and mechanical damage, ensuring your devices operate at their best.