What is Thermal Putty?

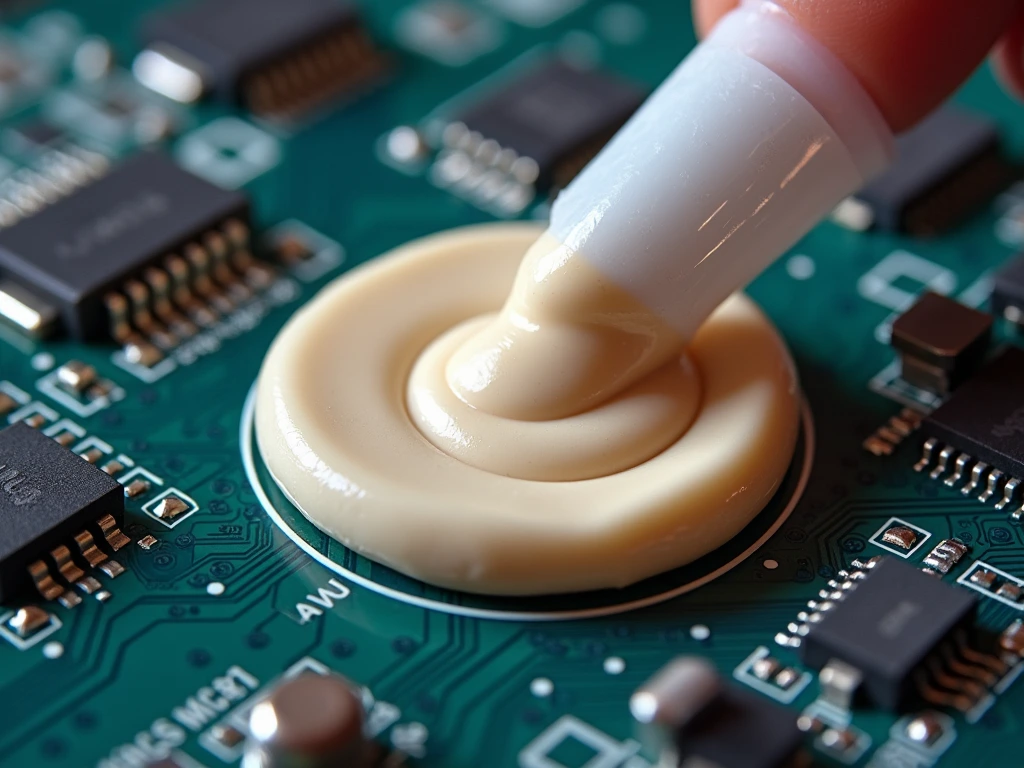

Thermal putty is a highly versatile thermal interface material (TIM) designed to efficiently transfer heat between electronic components and heat sinks. It provides a flexible solution for filling uneven gaps and ensuring effective thermal contact, which is critical for preventing overheating in electronic devices. With the increasing demand for compact and powerful electronics, thermal putty has become an essential material in heat management systems, offering unique advantages over traditional TIMs like thermal grease or thermal pads.

Table of Contents

H-putty

Shiu Li Technology has created a new advanced Thermal Putty interface material. LiPOLY H-putty is a tolerance filled, thermally conductive putty that maintains high compressibility with low stress, high reliability, and will not flow vertically. Our H-putty can replace thermals pads in design gaps of 0.1mm-3.0mm. H-Putty has a bond line thickness of 100-3000μm. The thermal conductivity of the H-putty series is 2.0/3.5/6.0 W/m*K.

LiPOLY’s Putty Series is gap filler material with a thermal conductivity 3.5~8.0W/m*K, high deformation amount, extremely low thermal resistance, low stress, flexible gap adaptation, and excellent tolerance compensation feature can overcome overflow and dryness problems. Ideally suited for LiPOLY Smart Dispense Robot which is the best choice for automated dispensing production.

See the complete thermal datasheet by visiting: Thermal Putty

LiPOLY TIM Technology : Thermal Solutions

Key Features of Thermal Putty

- Conformability: One of the standout features of thermal putty is its ability to conform to irregular surfaces. It is soft and easily moldable, allowing it to fill in even the smallest air gaps between components. This ensures complete thermal contact and minimizes thermal resistance, which enhances heat dissipation. Thermal putty is ideal for applications where precise thermal contact is required but where other TIMs might struggle to fill gaps effectively.

- Self-Leveling and Reworkable: Thermal putty’s self-leveling nature makes it easy to apply, as it spreads out evenly across surfaces under slight pressure. This property reduces the need for complex installation processes. Moreover, unlike some traditional TIMs, thermal putty is reworkable, meaning it can be easily removed or reapplied during maintenance or component replacement without losing effectiveness.

- Non-Curing: Unlike some other TIMs that require curing time to reach full effectiveness, thermal putty does not cure. This characteristic allows for instant thermal performance right after application, making it a more efficient solution for fast-paced production environments.

- Durability and Long-Term Stability: Thermal putty is known for its long-term stability, maintaining its thermal conductivity and physical properties over extended periods. It does not dry out or degrade, which ensures consistent performance over the lifespan of the device.

Applications of Thermal Putty

Thermal putty is commonly used in a variety of industries and applications, including:

- Consumer Electronics: It is widely used in smartphones, tablets, and laptops, where heat dissipation is crucial for maintaining device performance and preventing overheating in compact designs.

- Automotive: In electric vehicles (EVs), thermal putty plays a crucial role in managing the heat generated by batteries, powertrain components, and control modules.

- Telecommunications: High-power telecom equipment, such as base stations and antennas, often rely on thermal putty to efficiently dissipate heat generated by high-performance processors and other electronic components.

Difference Between Thermal Putty and Other TIMs

Compared to other TIMs like thermal grease or thermal pads, thermal putty offers distinct advantages:

- Better Gap-Filling: Thermal grease provides good thermal conductivity, but it may struggle to fill large or irregular gaps effectively. Thermal pads are easy to apply but may lack the flexibility needed for certain applications. Thermal putty combines the best of both worlds by offering excellent gap-filling capability and thermal conductivity in a flexible and easy-to-use form.

- Reusability: Unlike thermal grease, which may dry out over time, or thermal pads that may lose effectiveness after reinstallation, thermal putty can be reused and reworked, making it a cost-effective solution for long-term applications.

In conclusion, thermal putty is an excellent choice for managing heat in high-performance, compact devices. Its flexibility, reusability, and superior gap-filling properties make it a highly effective TIM for modern thermal management challenges.