Thermal Gel vs Thermal Paste: What’s the Difference?

When managing heat dissipation in electronic devices, Thermal Gel and Thermal Paste are two of the most commonly used materials. Both serve the same primary function: improving the transfer of heat between a heat source, like a CPU or GPU, and a heatsink. However, they differ in their composition, application, and performance characteristics. They also provide better coverage over larger surface areas and remain stable even under thermal expansion or contraction.

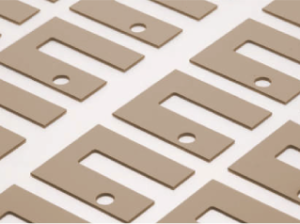

Product Catalog : 🔗 Thermal Gel 🔗 Thermal Paste

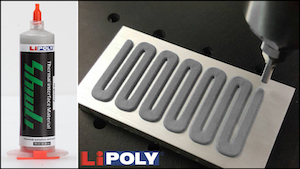

What is Thermal Gel?

Thermal Gel, on the other hand, is softer and more flexible than thermal paste. It is typically used in environments that require long-term stability, where the material needs to maintain its properties over time under varying thermal cycles. Suitable for applications requiring one-time bonding.

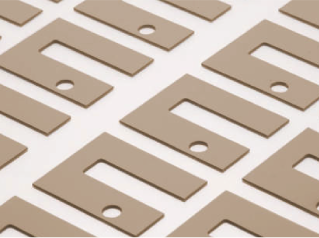

What is Thermal Paste?

Thermal Paste, also known as thermal grease or thermal compound, is a high-viscosity substance designed to fill microscopic air gaps between surfaces. It usually consists of silicone or non-silicone-based compounds combined with thermally conductive fillers such as metal oxides or ceramic powders. Its main advantage is its widespread availability, ease of use, and affordability, making it ideal for a range of applications in both consumer and industrial electronics.

Key Differences

-

Consistency and Application: Thermal Paste is thicker and requires precise application to avoid excess buildup, while Thermal Gel is more fluid and self-leveling, making it easier to apply over larger surfaces.

-

Thermal Performance: Although both materials conduct heat well, Thermal Gel generally offers better long-term thermal stability, especially in high-performance applications where the system undergoes frequent thermal cycling.

-

Durability: Thermal Gel tends to last longer in challenging environments, as it resists drying out and hardening over time, while Thermal Paste may require reapplication after extended use.

Choosing the Right Material

The decision between using Thermal Gel or Thermal Paste depends on your specific needs. For regular consumer electronics and one-time applications, Thermal Paste is a cost-effective solution. However, for long-term reliability in more demanding environments, Thermal Gel provides superior durability and thermal performance.

LiPOLY TIM Technology : Thermal Solutions